Lesa¶

The site – Pilot Area Selection_ – Documentation of the installation – Results

The site¶

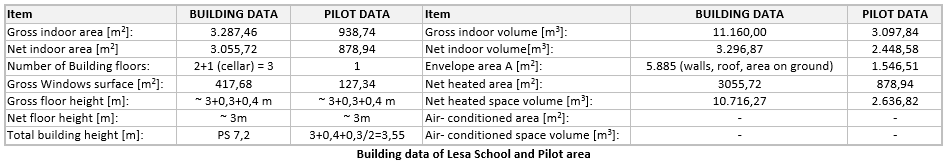

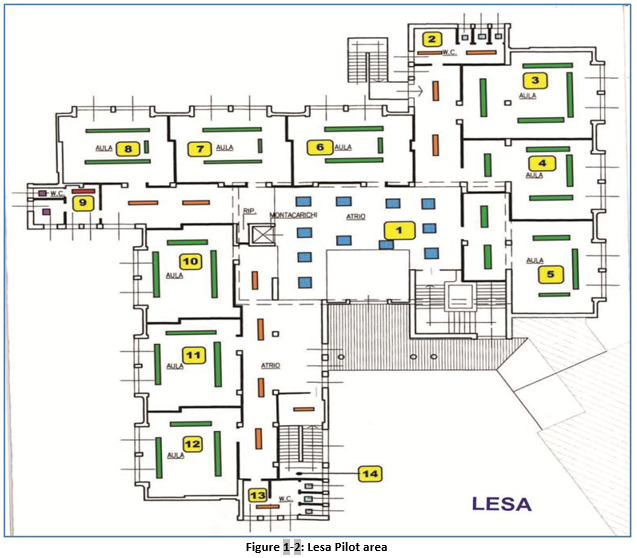

The the town of LESA is located in the Lago Maggiore region (province of Novara) in the North-West of Italy. The Elementary and Middle-grade school is a single building built in 1974 with total area of 3,056 m2 and heating volume of about 11,160 m3. It is a two story building that during the school year hosts an average of 220 people (both staff and students). The building is a typical construction of the 70s and did not have any specific energy savings provision. The Municipalty, who is the owner of the school, underwent an important restructuring plan to realize energy savings by substituting the heat generators, installing solar panels and adding insulation material specifically under the roof top. Pilot area is the first floor, and has net indoor area of 939 m2. Pilot consist of classrooms, laboratories, offices, library, lobbies, corridors and WC-s. Pilot area hosts approximately 102 people.

Pilot Area Selection¶

The Pilot area is the overall 1st floor of the building, which hosts 9 Classrooms, 3 Bathrooms, Service Rooms, Entrance, Lobby and Corridors.

Documentation of the installation¶

The Lesa Pilot has been considered as a “laboratory”, where the basic ideas of the DOKI Bems have been implemented and verified. For this reason the physical and interfacing solutions adopted for Lesa are sometimes different from those subsequently applied in the other 3 Pilots; but from the functional and use point of views affecting VSNavigator, the Bems performances in Lesa are identical to those of the other 3 Pilots. The installation of the EVO Modules, sensors and actuators have been performed wiring on site all components, including the ancillary components necessary to the operation of the EVO Modules themselves (like power supply, switches, overload circuits, connection terminals, etc.). The whole set of documentation, detailing drawings, layouts, technical specification of equipment and cabling was produced with the objective of enabling the installer to perform the specific tasks while minimizing the possibility of making errors. More in detail, document production included:

- a list of modules and units to be installed in the Pilot, including the code number of each unit;

- a general drawing which summarizes the links between the various modules that constitutes the Pilot with specific details of the type of cable to use for all connections (see figure in the next section);

- a wiring diagram for each EVO Module (both for control of rooms/premise and for measure of energy) that shows the connections to be performed and the type of cable to be used for each input or output (see figures below).